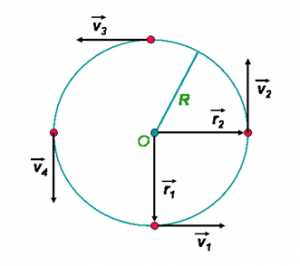

Circular Motion in physics is defined as rotation along a circle, such as a satellite orbiting Earth, an electron moving perpendicular to a uniform magnetic field or a gear turning inside a mechanism.When uniform, circular motion has a constant angular rate of rotation; when non-uniform, it has a changing rate of rotation.

Calculator: Circular Motion Equations Formulas

Uniform Circular Motion (tutorial): Covering formulas and definitions for Displacement, Velocity, and Acceleration in uniform circular motion.

General Gear Glossary

Gear – Used within a transmission device, gears are driven by a rotational force. Gears are designed so the teeth interlock with another gear (or device). By doing so, the first gear transfers the originating rotational force to another gear (or to one or more gears). Gear systems can also be combined using gears of unequal diameters – creating mechanical advantages, such as having the rotational speed and torque of the second gear that are different from the first gear.

Gear Ratio – Whether defining the “ratio of rotational speeds” between two meshing gears or the first and final gears in a set of gears, the gear ratio formula divides the number of teeth on the larger gear by the number of teeth on the smaller gear (or “pinion”). If one gear had 14 teeth and the other had 40 teeth, the gear ratio (40/14) equals 2.85.

Mechanical Advantage – A factor used in physics and engineering, mechanical advantage (MA) is defined by how much the machine multiplies or reduces the force or torque applied to it. This factor is applied to make work easier and faster. To calculate the MA of a machine, divide the resistance force by the effort force. When calculating the rate of mechanical advantage, other working factors are also taken into consideration, such as the amount of energy that is lost due to friction generated during a given task.

Sprockets – A profiled wheel with teeth that mesh with a chain, track or other perforated or indented material. Sprocket chains are connected links used to transfer power in machines through links designed to mesh with the teeth of the sprockets of the machine. Typically, these chains are only flexible in one dimension.