Cogmatic customers are often faced with a variety of custom large gear and large sprocket manufacturing challenges. Some challenges are more typical than others, while some are specific to the customer’s needs.

- Making Noodles

- Short-Term Production

- Prototype Testing

- Design Engineering Support

- Chain Wear & Breakage

- Sprocket Teeth Breaking

- Reducing Downtime

- Re-Engineering Challenges

- Early Chain & Sprocket Wear

- 14 to 18-Foot Segmented Gears

Making Noodles: Flame Machining and True Shapes

Product: Girth Sprockets

Industry: Aggregate Processing

As rotating drums for processing aggregate materials have become larger, the room around them hasn’t. This has resulted in girth sprockets that need to be big enough for large roller chains or even engineered chains, but with much less height from the ring sprocket ID to the root diameter. The result for customers is less material for a lower cost than a big ring sprocket, but the downside is that the small cross-section makes for a very flexible part, referred to in the trade as a “noodle”. The challenge of manufacturing a part (that has all the stiffness of a wet noodle) is how to make it without distortion. This problem is complicated because these large rings have to be split after manufacturing to make them ship-able, and “noodles” spring when they are split.

Over the last couple of years, Cogmatic has been working with customers who wanted lower costs than conventionally cold machined sprockets, but also needed consistent parts because they make standard sized large drums. By bringing together our experienced shop personnel and our outside vendors, Cogmatic has established a process that includes adjusting the ring as it is cut, stress relieving after cutting, and locking it down with angle iron for distortion-free shipping and in-process inspections. The results are parts provided with minimum material for lower costs, true round shapes, and no twisting over the circumference of the part.

Meeting Short-Term Production Needs

Cogmatic Flame Machining delivers high-volume sprockets

Customer:

A U.S. manufacturer of undercarriage assemblies.

Product:

Large sprockets with unusual tooth forms

Challenge:

Cogmatic supplies this customer with a variety of fabricated crawler sprockets for undercarriage assemblies. Many of these sprockets required specialized customer specs, including unique designs, unusual tooth forms or were low volume specials. For most of their higher volume undercarriage assemblies, the customer had been using machined cast sprockets. When transportation costs and overseas lead times escalated, they found they were no longer able to meet all of their customers’ demands.

Cogmatic Solution:

They approached Cogmatic for proposals on a number of parts that were castings. Cogmatic is now fabricating the needed parts, enabling them to meet and satisfy their customers’ demands.

When the company’s sales team learned more about Cogmatic’s involvement, they asked their Purchasing department to inquire if Cogmatic could make parts for “old” undercarriage assemblies that were no longer in production. Now, Cogmatic is fabricating small production orders to continue keeping their customers’ equipment in the field.

The Rest of the Story:

— Customer Follow-up —

When shipping costs, production runs and lead times stretched out, the customer found that the only way to satisfy their customers was to come to Cogmatic for custom fabricated sprockets.

We are aware, as anyone, that manufacturers in developing countries can produce machined castings at incredibly low cost. But, to use that advantage, companies must have a clear view of production requirements and plenty of lead time.

When the market changes, product requirements shifts or customers won’t wait for the “slow boat to arrive”, Cogmatic can step up to the task and help smooth out production requirements with fabricated parts.

EXPECT US TO MEET YOUR HIGH VOLUME SPROCKET MANUFACTURING CHALLENGES

Prototype Testing

Product: Large, Heavy Crawler Sprockets-Split Version

Cogmatic has made very large, heavy crawler sprockets for one of our customers for years. These parts have an unusually large bore and the customer always wanted the part in one piece to avoid distortion. They were also concerned that the rather thin cross section might shift slightly under load, experiencing greater wear at the split line. Having the sprockets made in one piece meant that changing out a worn out chain and sprocket required a significant tear down of the machine since the hydrostatic drive unit had to be removed in order to remove the sprocket. That was very unpopular with their customers.

Cogmatic manufactured and continues to provide the customer with split versions of the sprocket for field testing. Units are in the field now showing no difference in wear and promising a much easier change out for our customer’s customers when it is time to change the parts over.

Fabricating New Rotator Gears

Cogmatic helps customer develop new equipment offerings

Customer:

A major manufacturer of rock crushing equipment.

Product:

Rotator Gears and companion drive pinions

Challenge:

The company was tasked with introducing three new models of rock crushing equipment over the past several years. They needed assistance with fabricating the rotator gears and companion drive pinions for these new models.

Cogmatic Solution:

Since Cogmatic had a solid relationship with the customer, the customer came to Cogmatic for assistance each time a new model was being developed.

In fact, at one point the customer’s engineering contact confided, “We wouldn’t think of asking anyone else to build these gears for us. Cogmatic’s combination of quality, on-time delivery, and overall value is just outstanding. We never have problems with the products you make for us.”

By building strong relationships with each customer and making sure any issues are addressed to their satisfaction, we can provide value to our customers time and time again.

The Rest of the Story:

— Customer Follow-up —

Recently, this customer decided to offer a small crusher to their market. Because they recognized that their targeted customers were extremely cost-conscious, one of their key concerns was cost.

Cogmatic helped in the design of the part by providing manufacturing advice that met their cost objectives. We also provided alternate quotes for different methods of manufacturing, which enabled the customer to choose the best alternative for their fabrication cost needs.

The engineer commented, “Thanks for presenting these options… The manufacturing plan you proposed for that option is exactly what we had in mind when we designed and detailed this part.”

Solid Sprocket Corrects Chain Wear and Breakage

Cogmatic quality helps customer standardize

Customer:

A South Dakota manufacturer of trommels

Product:

Solid Ring Sprocket (vs. Segmented Sprocket)

Challenge:

The customer was having a number of quality issues that were leading to complaints by their end users.

The customer had been welding five or six flame cut individual segments together to form one ring sprocket. Unfortunately, welding that many segments together to form a concentric ring was extremely difficult – and the results were disappointing. The customer was troubled with:

- Rapid Chain Wear

- Noisy Operation

- Misalignment between the Chain and Sprocket

- Uneven Chain Loading

Many extra hours of labor were needed to assemble each ring sprocket.

They also were running into issues with their supplier holding tolerances on drum concentricity. The customer often had to send segments back for re-rolling or had to re-adjust them in their plant for varying tolerances. They were wasting a lot of time correcting supplier problems.

Cogmatic Solution:

Our large sprocket specialists at Cogmatic offered this customer a sprocket made as a solid ring. Their installers could simply slide it over the drum section and weld it into place. The solid sprocket formed a uniform concentric circle, resulting in longer chain life; quieter operation; proper alignment between the chain and the sprocket; and even chain loading patterns. It also reduced installation labor by six hours. Best of all, the price was similar to what they had previously been paying for inferior parts.

The customer was so impressed with Cogmatic’s quality, delivery, and value that they started using Cogmatic to make all of their drum segments needed to fabricate four models of trommel screens.

Cogmatic’s ability to provide concentric, uniform drum segments and deliver those quality parts JIT has helped their customer reduce installation time; provide a quieter operating machine, and increase the number of turns on their inventory. Cogmatic now supplies four (4) kits – with all the needed parts arranged in assembly order on two (2) or three (3) skids. The delivered skids are placed on the customer’s assembly line so workers can efficiently pull the parts off the skids in the order needed to complete each trommel screen.

The Rest of the Story:

— Customer Follow-up —

The customer is now using Blanket Orders, which allow them to send us an email asking for a release and to have their kits on their plant floor within ten (10) days.

Improved Sprocket Tooth

Cogmatic lets customer focus on big picture

Customer:

A major manufacturer of trenching equipment.

Product:

Crawler Sprockets

Challenge:

The customer had field problems that involved teeth breaking off of the crawler sprockets that were fabricated in their own facilities. These sprockets propel the undercarriage assemblies used to drive a variety of large commercial trenching machines. After a number of attempts to correct the manufacturing difficulties, they were looking for a company with expertise in crawler sprocket and tooth profile manufacturing.

In fact, a company executive said, “Why don’t we stick to what we do best and find a company whose business it is to know how to fabricate quality crawler sprockets?”

Cogmatic Solution:

The customer was familiar with Cogmatic since they already fabricated sprockets used elsewhere in their machines. They came to Cogmatic for advice and eventually contracted with Cogmatic to fabricate their crawler sprockets instead of doing them in-house. After reviewing their sprocket tooth profile and application, Cogmatic now produces crawler sprockets for four different undercarriage assemblies and will soon add several more new products.

Field product failures have ceased, warranty issues for this problem have been dramatically reduced, and Cogmatic further strengthened a relationship with a valued customer.

The Rest of the Story:

— Customer Follow-up —

We have also helped this customer with a large sprocket that had been machined internally. The customer’s equipment was old and not doing a very good job. Plus, they needed the additional manufacturing space.

Now, we make their special sprocket for a lug-less chain, which runs smoother with less wear than their in-house manufactured part. The client gained floor space and saved money.

Flame Machined Parts Reduce Maintenance and Downtime

Cogmatic helps Ag customers get down on the farm

Customer:

An agricultural equipment manufacturer.

Product:

Large sprockets

Challenge:

The customer was looking to reduce the need for equipment maintenance, which led to farmers being out of the field. They were looking for a solution that would increase sprocket chain wear and overall lifetime.

Cogmatic Solution:

For several years, Cogmatic would flame machine the teeth on two large gears used in the customer’s Vertical Feed Mixer. When they needed similar machining for their large capacity Side-Discharge Manure Spreaders, they came to Cogmatic asking for quotes on a range of large sprockets and hub assemblies.

Cogmatic Flame Machined parts for the customer, providing improved axial and radial run-out that reduced chain wear and extended life.

The customer was so pleased with the results that Cogmatic has been contracted to make additional large sprockets for other equipment in their product line. When they need to get down on the farm, Cogmatic is there for them.

The Rest of the Story:

— Customer Follow-up —

Most recently, this customer took our relationship a step further and placed Cogmatic on their Kan-ban program.

With the aid of weekly inventory and forecast updates, Cogmatic schedules our production to meet the customer’s needs. Kan-ban Release Orders can come to Cogmatic as few as four (4) calendar days before the mill run pick-up.

To date, Cogmatic has 100% on-time delivery to this customer.

Ring Gear Part Re-Engineered for Customer

Cogmatic helps customer replace worn-out gear versus entire equipment

Customer:

A U.S. manufacturer who specializes in rebuilding older drum systems.

Product:

Ring Gear (part)

Challenge:

Their customer had a very large drum with a ring gear that needed to be replaced. The problem was that the gear part was very old and no longer being manufactured. They had no drawings, specs or catalog information about the gear – except the name of the original manufacturer of the equipment.

Although the rest of the system was functional, if they couldn’t replace the worn-out part, their customer was faced with purchasing a brand new assembly. At the time, the end-user felt they could not make the economic justification for purchasing new equipment.

Cogmatic Solution:

When our customer approached us for assistance, they provided our team with the Outside Diameter of the drum and a count of the remnants of the worn-out teeth. Along with some field measurements taken by their customer, Cogmatic was able to determine what the Ring Gear specification would have to be. Cogmatic still required an unknown factor: What was the pressure angle for the gear?

Making a Gear… when all you have is a Pinion

To solve this part of the puzzle, the customer purchased a replacement pinion from a company that specializes in maintaining stocks of old obsolete parts. Working with one of our vendors, Cogmatic was able to take appropriate measurements of the tooth form and verify the pressure angle. With that specification confirmed, we were able to make the ring gear. Our customer replaced the gear and pinion and their customer enjoyed the renewed functionality of their equipment without investing in a new system.

MEETING CUSTOMER NEEDS AS A LARGE RING GEAR MANUFACTURER

Smoothing Out a Tooth Form

Cogmatic solves early chain and sprocket wear with modified tooth

Customer:

A major manufacturer in stationary concrete mixing plant industry.

Product:

Large sprocket

Challenge:

Cogmatic was asked by an existing customer to quote on a sprocket that had been in use for many years on one of the division’s basic machines. The machine is a real breadwinner, solid old design, but with periodic modernization was still a consistent seller. The only issue with it had been the early chain and sprocket wear. When they came to Cogmatic, they were facing continued manufacturing in-house on old equipment or farming out manufacturing to us as an existing vendor, and hopefully, creating some needed space in their plant for new manufacturing equipment. If we could make it more durable and last longer, then so much the better.

Cogmatic Solution:

Since Cogmatic had a solid relationship with the customer, the customer came to Cogmatic for assistance each time a new model was being developed.

Because we had never made this part before, Cogmatic had to develop a profile cam to Flame Machine the tooth form to the proper shape. In working on a study of the tooth form detail, our team discovered that the drawing, if it was faithfully reproduced in the metal, resulted in a subtle bump near the pitch line. Basically, two radii didn’t quite meet where they were supposed to.

When we shared this finding with the customer, we also presented a suggestion for their review that smoothed the transition from tooth flank to tooth tip. Our customer examined our detail drawings and had that “aha!” moment where they realized this bump (or hook), was the source of the excess wear and the rough operation.

The customer reviewed our suggestion and re-designed their part asking for a quote per their revision. Since Cogmatic has been making the part, they are enjoying smoother operation and seeing longer life with reduced wear.

Sometimes it is a very subtle but simple thing, as you can see from the detail of the before and after tooth form, but that can make the difference between just working and working really well. Cogmatic will do the detailed analysis to make sure that we understand our customer’s custom design requirements. We usually don’t find bumps where the customer didn’t want them to be, but it’s good to know that we are a vendor that will assume nothing and check everything.

Besides a 14-Foot Segmented Gear, Can You Make Two 18-Foot Gears for Us?

Cogmatic steps up to customer challenges

Customer:

A rock crushing equipment manufacturer.

Product:

Large Gears

Challenge:

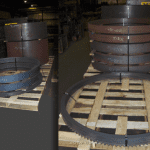

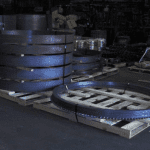

Our customer that manufactures rock crushers had a problem. While we made a number of gears for them, we did not make the largest one. The biggest machine they made used a 14-foot diameter gear that was made in (4) segments then welded together. Shipping this to their customer at the finished size presented a big problem. Therefore, they designed a version of the gear with four-lap joints that would be bolted together at their customer’s job site.

Their current large gear vendor had made several attempts at manufacturing the lap-jointed gear. They finally determined that this was not something they could do at the quality level needed. When Cogmatic was brought into the picture, it was to discuss how our team might go about making this gear. Before the discussion about our proposed manufacturing method was over, our customer said, “OK that’s a great approach, but we also really need you to make one that is 18 feet in diameter first. Oh, and by the way, not one, but two gears! And we’ll also need them made as soon as possible!”

Cogmatic Solution:

With our egos thoroughly flattered, but our manufacturing concept unproven, our team gathered to evaluate the potential pitfalls of making these gears. With the help of our team of suppliers, we answered every question about flatness, joint overlap, tooth form displacement, Flame Machining across a joint, heat treatment and assembly.

Thus fortified, we put in place a plan of attack. With lots of discussion with our customer’s engineers, our vendors, and our experienced employees, the gears were completed. Sent to the site, they were assembled and have been functioning faultlessly since October 2011.

Stepping Up to Customer Challenges

Cogmatic can’t do everything, and we’ll tell you when we can’t. But when there is a challenging application, we will do everything we can to help our customers.

The manufacturing of this 7,000-pound 18-foot diameter gear is featured in our company video and the pictures below. You probably won’t need something that big, but it’s nice to know that when you are working with Cogmatic, you are working with a company that can do this kind of part.