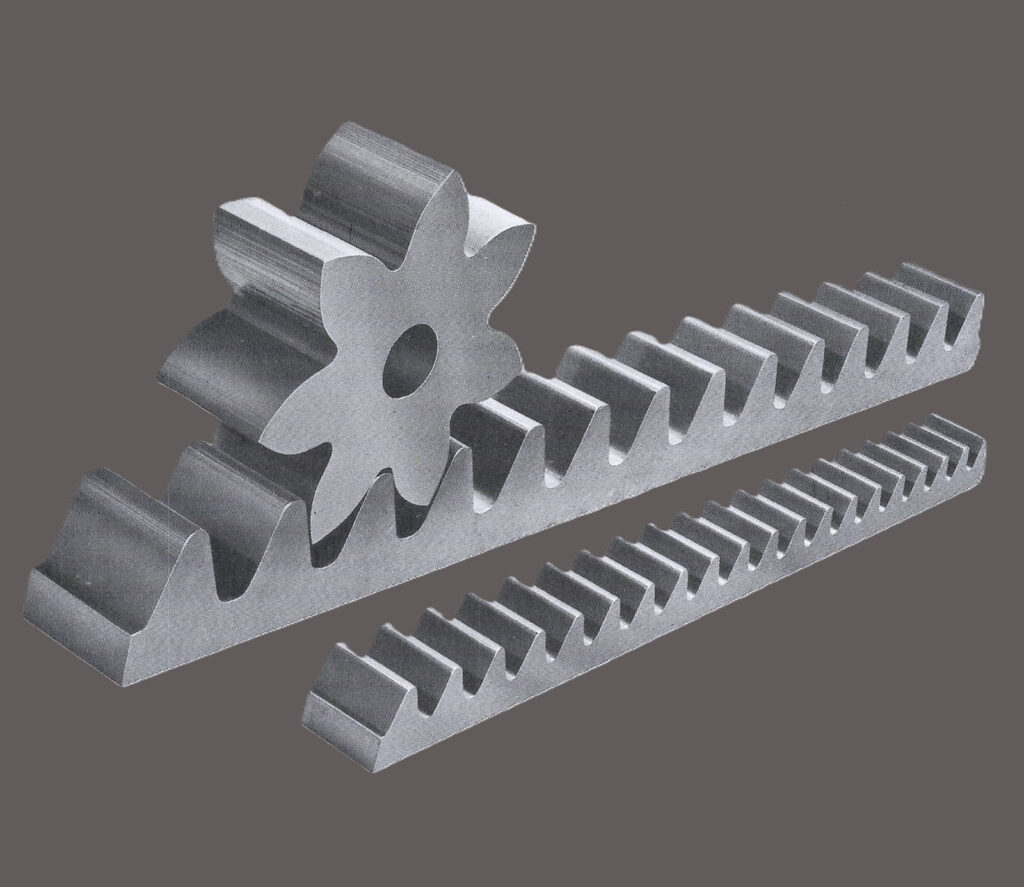

Our custom gear racks can range in profile from 3 to ¾ diametral pitch and up to 48 inches in length and a face width of up to 6 inches. Applied in furnace doors, mining drills, wastewater treatment and cable laying equipment, Cogmatic’s gear racks have a symmetrical tooth profile to help minimize wear and maximize performance. And like most of Cogmatic’s products, our gear racks can be Induction case hardened or through hardened for incredible toughness.

From custom gear racks to large drive pinion gears, your industrial projects may need Cogmatic Flame Machining technology to experience improvements in longevity, quality and affordability.