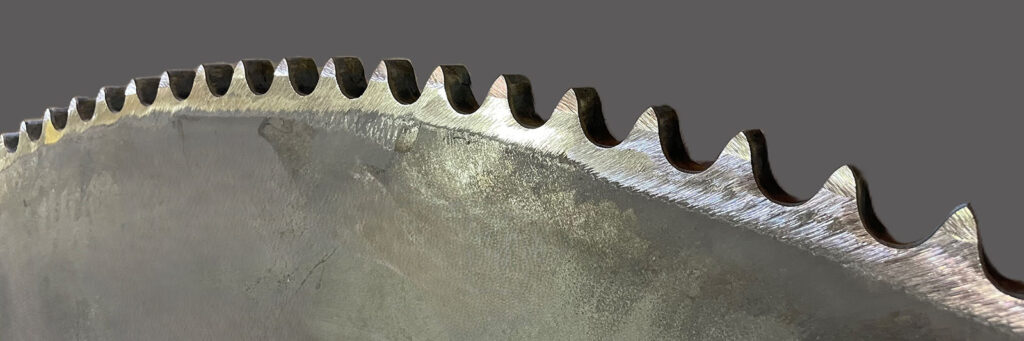

Cogmatic Flame Machining creates accurate tooth spacing, smooth finish and a consistently precise, square tooth profile. Because we can fabricate large sprockets and spur gears at an affordable price and without long lead times or turnaround, you may consider flame machining for your next project – instead of flame cutting or cold machining.

Cogmatic’s Flame Machining is a Proprietary High-Pressure, Oxy-Propane Cutting Process

Our flame machining technology is both technically and economically competitive with conventional manufacturing metal-cutting processes. Using our proprietary high-pressure, oxyfuel gas cutting system, Cogmatic Flame Machining cuts metals by means of a chemical reaction of oxy-propane and metal at elevated temperatures. The required temperature is maintained by the flame, which is generated from the combustion of the oxy-propane gas.

As the jet of oxy-propane is positioned within the preheated area, the chemical reaction occurring between the oxy-propane and metal, creates iron oxide (or “slag”). As the force of the oxy-propane jettisons the slag away, the flame can accurately pierce through the material.

By means of a dual-axis drive system, we carefully control both the path and speed of the flame – creating a consistently sharp cut (profile), with minimal thermal stress of the material.

Typical Runout Tolerances

- AGMA 5-6 for Gears

- ANSI B29.1 for Sprockets

Our technicians use their experience and expertise to keep production run setups quick and simple – keeping this an economical process with quick turnaround time. All highly-desirable traits for selecting your gear or sprocket manufacturing vendor.

Strength, Hardness and Durability

Learn more about the heat treating, quenching and tempering stages in our Flame Machining Technology process.